PRODUCT DETAILS

CLASSIFICATION OF THERMAL HYDRAULIC PUMP

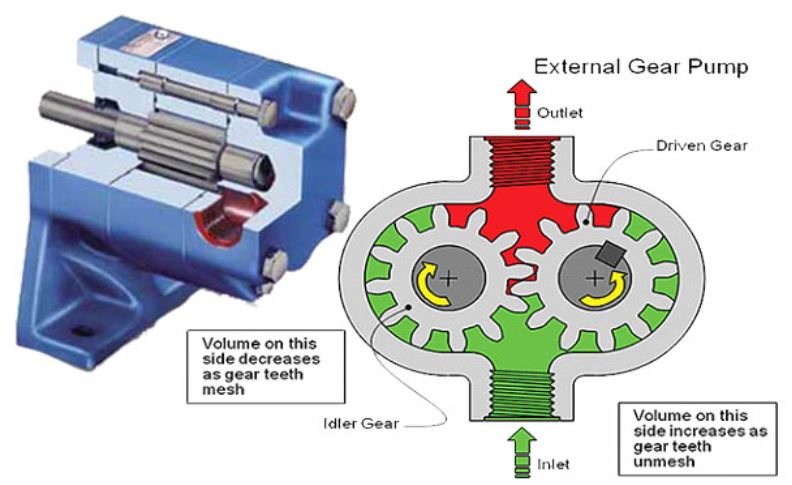

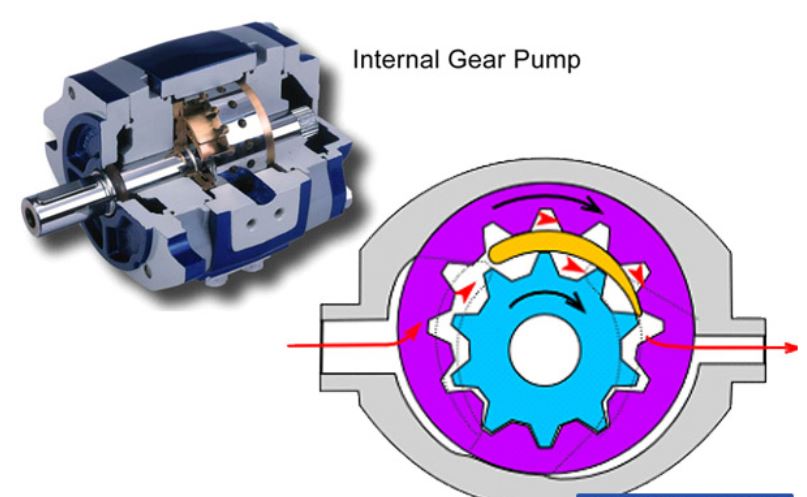

There are 2 types of hydraulic gear pumps including

On the market today, the external gear pump is more widely used due to its simpler construction, low cost, but the hydraulic gear pump is only used in systems with medium pressure.

When the active gear rotates, the engaged passive gear also rotates. When this gear is engaged, it will create 2 areas that are joint and joint together.

At the outlet zone the increased volume causes the pressure to decrease, so the liquid will be filled in this area. The cogs transport the liquid according to the zone to the joint

At the same joint, the teeth are engaged, making the volume decrease and at the same time, the pressure in this area increases. Since the gears rotate at the speed of the electric motor about a few thousand revolutions per minute, the fluid glide produced is a lot. So after the process on the generated liquid transmits energy => that is the working principle of the gear pump

HOW TO CHOOSE WHEEL HYDRAULIC PUMP

The pump is selected according to 2 parameters and individual flow rate, maximum pressure. Density is the amount of liquid in a ring that the pump generates. Based on the rotation speed of the electric motor how many rpm / min, we can calculate the pump flow per unit time

The maximum pressure that the pump can create affects the performance of the pump. If you choose a pump with low pressure, it will create the required pressure for the hydraulic system

Note necessary when choosing a pump is not always select the maximum pump capacity of the system, before choosing we must observe the operating graph of the machine. In a period of time what maximum flow we need is, in some cases can use a accumulator and 1 gear pump with small capacity