PRODUCT DETAILS

The screw pump in English name is Progessive cavity pump or also known as Screw pump, which is more popularly known as chicken gut pump. The reason for this name is that the internal structure of the pump body is driven by a helical shaft. Depending on the type, there will be single, double or multiple twisted twists. The main components of the pump include the seal, shaft, rotor and stator. Depending on the pump substance and the pump temperature, there will be pumps suitable for each substance.

Screw pumps are also one of the series of pumps that have many applications, especially in the wastewater treatment industry, so if you want to use a shaft pump, users cannot forget the special applications of this pump. .

To learn more can go to the article:

So how is the application of the screw pump to the wastewater treatment industry, and we will find out in this article!

Screw pumps and wastewater treatment applications

The wastewater treatment industry has many applications and is used with many different pumping systems, so if you want to use an efficient screw pump, you need to carefully understand this pump as well as its applications. it and the structure and principle of the pump's operation.

Screw pump is the main product line used in wastewater treatment projects, used to pump liquids with high viscosity or strong corrosive properties such as mud, pressed fruits, molasses ...

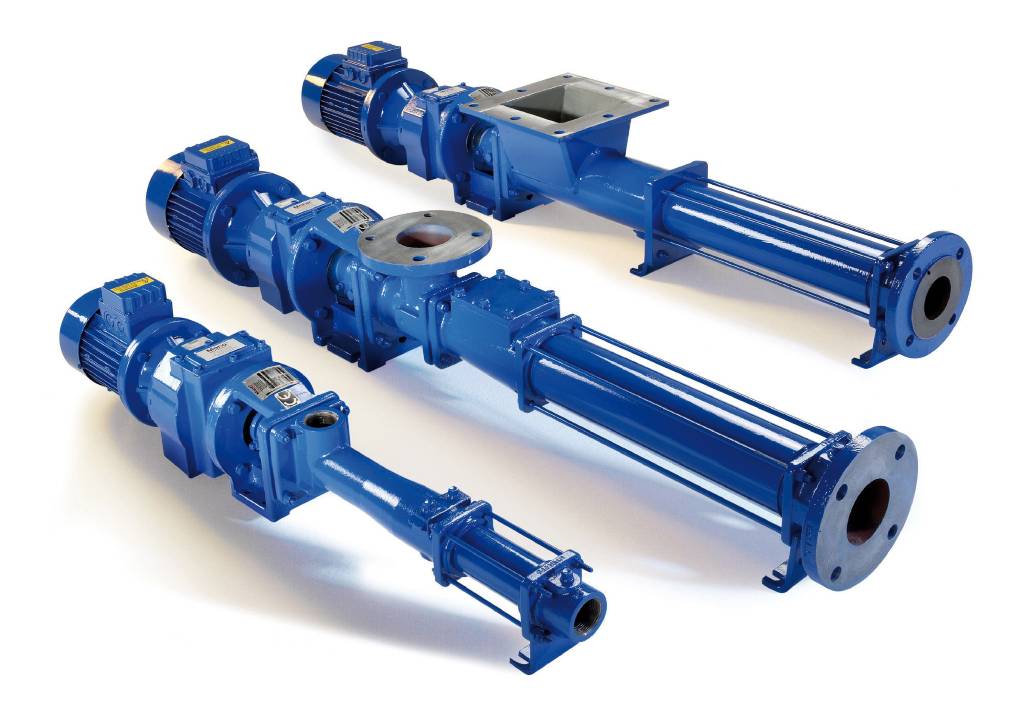

There are many different types of screw pumps that the user can choose from for wastewater pumping applications such as cast iron body screw pump, aluminum alloy, and stainless steel; screw pump with body and interlock motor connected by coupling; low pressure, large flow screw pump; High pressure, low flow screw pump. These types of screw pumps have separate applications and for different industries as well.

Operation of the screw pump is quite simple, when the screw is in motion, the pump is pushed along the pump shaft techniques from the suction head to the discharge outlet and out, the pressure is generated by the pump motor, so the pump shaft is pumped. The screw is not capable of priming and is incapable of running

A screw pump during work will result in poor quality components over time. So in order to improve the life of screw pumps, avoid dry friction, improve pumpability by pouring water or other liquid pumped in from a neutral environment.

For a wide variety of applications, screw pumps are highly regarded for their quality and performance. Each screw pump is made of different materials for different purposes. Horizontal screw pump is used in the fields of transporting sludge, fluid in unhygienic environment. The stainless steel body screw pump is widely used in the food and pharmaceutical industries.